Welcome to Tangshan Moneide Trading Co., Ltd.

rubrene

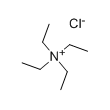

Rubrene for next‑gen optoelectronics: what labs and fabs are really buying If you work in OLEDs, OFETs, or photon upconversion, you’ve almost certainly handled rubrene at some point—probably with a mix of excitement and caution. It’s a classic organic semiconductor, fluorescent, stubbornly crystalline, and—when purified right—capable of wildly impressive charge mobility. I’ve seen teams move from “good enough” grades to high-purity material and unlock order-of-magnitude jumps in repeatability. That’s not hype; it’s process control. What it is (and why it still matters) rubrene (Synonyms: 5,6,11,12‑Tetraphenylnaphthacene; CAS 517‑51‑1) remains a benchmark p‑type organic semiconductor. In single crystals, mobility can reach the teens (cm²/V·s), which is still jaw‑dropping. In thin films, you won’t hit those numbers, but you’ll get reliable hole transport and a bright yellow‑orange emission band—handy for OLED dopants, scintillation, and triplet–triplet annihilation upconversion (TTA‑UC). Industry trends I’m seeing Shift to tighter spec windows: HPLC ≥99.5% and metal ppm controls for device stability. More gradient-sublimed lots for pilot lines; batch-to-batch certificates are now table stakes. Growing demand for TTA‑UC in sensors and niche photovoltaics; OLED dopant use is steady. Product specs (typical, real-world use may vary) Chemical name 5,6,11,12‑Tetraphenylnaphthacene ( rubrene ) CAS No. 517‑51‑1 Purity (HPLC) ≥99.5% (typical lots 99.7% ≈) Melting point ≈329–331 °C PL peak (solution) ≈560–570 nm; thin‑film red‑shift possible Residual metals QC methods HPLC, NMR, MS, TGA (ASTM E1131), DSC, UV‑Vis, XRD Where it’s used OLED dopant (yellow emitter) and host blending experiments. OFET channel layers; single‑crystal mobility benchmarks. TTA‑UC systems with Pd‑/Pt‑porphyrin sensitizers for low‑light sensing. Scintillator research and organic lasers—niche but interesting. Process flow you can actually replicate Materials: technical‑grade rubrene feedstock; high‑purity nitrogen/argon; quartz boats. Methods: multi‑step gradient sublimation under high vacuum; optional zone‑refining for R&D crystals. Testing: HPLC area %; ICP‑MS for metals; TGA/DSC; PL/absorption mapping; XRD for crystallinity. Standards: ISO 9001 QC framework; ISO/IEC 17025 lab methods; ASTM E1131 for TGA; IEC 62341 guidance for OLED device testing environments. Packaging: amber glass, inert back‑fill, moisture/oxygen barrier pouch. Service life: 24 months sealed at 2–8 °C, dark, inert; open handling in N2 glovebox recommended. Industries: display R&D, wearables, sensors, academic materials science, photonics startups. Vendor comparison (indicative) Vendor Purity QC docs Lead time Customization Moneidechem (Hebei, China) ≥99.5% HPLC COA + HPLC + ICP‑MS 7–12 days ≈ Lot size, metal‑ppm targeting Supplier B (global) ≥98–99% COA 10–20 days Limited Supplier C (R&D focus) ≥99% COA + NMR Stock dependent Small‑batch only Customization and feedback Teams often request tighter ICP‑MS thresholds for rubrene (e.g., Fe, Cu, Ni Origin and logistics: 2‑7‑523 Jidong Building Materials, Tangshan, Hebei 064000, China. Export documentation usually includes COA, MSDS, and REACH/RoHS declarations. Quick case notes OFET group improved mobility from ~0.7 to 1.4 cm²/V·s in thin films after switching to gradient‑sublimed rubrene and oxygen‑scrubbed solvents. TTA‑UC team reported 15–20% stronger UC emission at the same pump power with low‑ppm‑metal lots (same device stack). Safety and handling Handle rubrene in a dry N2 environment; minimize light/oxygen exposure. Follow standard PPE. Dispose according to local regulations; consult MSDS. References Podzorov, V. et al. High-mobility field-effect transistors based on single-crystal rubrene. Applied Physics Letters 82, 1739–1741 (2003). Cheng, Y.-Y. et al. Solid-state visible-to-UV photon upconversion via TTA using rubrene. The Journal of Physical Chemistry Letters 1, 1795–1799 (2010). ASTM E1131-20: Standard Test Method for Compositional Analysis by Thermogravimetry. IEC 62341: Organic light emitting diode (OLED) displays – Performance requirements. ISO/IEC 17025: General requirements for the competence of testing and calibration laboratories.

look at newproducts